The world of paper manufacturers is composed of a limited number of large (often multinational) companies governed by principles of efficiency that coexist with a parallel world made up of countless small/medium-sized paper mills with a long family history. The latter are usually equipped with obsolete plants that, leading to waste and high consumption, are expensive and inefficient. Over time, however, technology has not been the only factor that has evolved; in fact, the market has also undergone changes. The paper industry is very different from a few years ago: demands have changed considerably, competition has increased, and there is a growing need to ensure that the production process uses raw materials in the most sustainable way, with minimal environmental impact, from resources to recycling. Thus, to be competitive and successful, but often just to be able to survive, paper mills should make their production more efficient and increase yield. Hence the need for many companies to modernize their plants: an intervention that A.CELLI, thanks to its experience, can guarantee through customized technical solutions to meet the specific efficiency and safety requirements of both large and smaller companies.

The impact of the shoe press on productivity

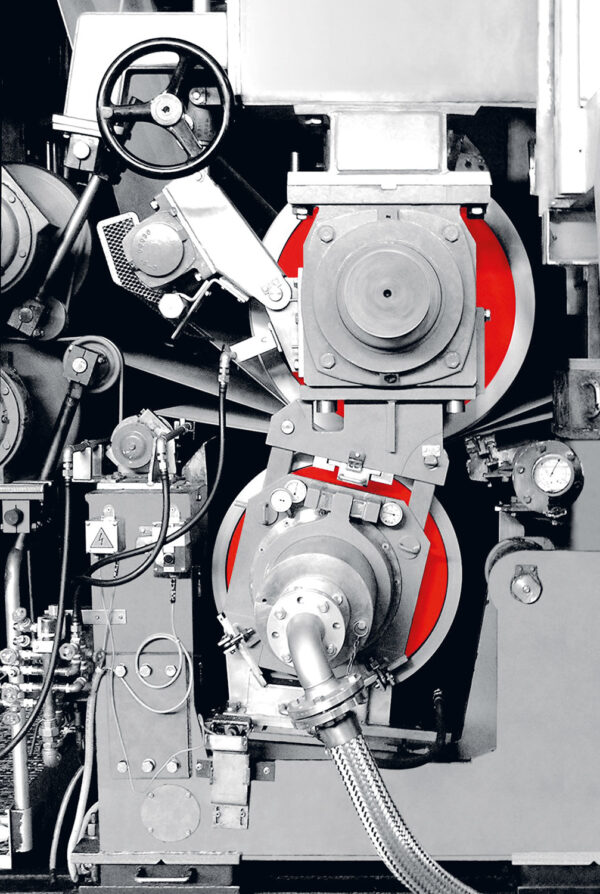

The wealth of papermaking expertise that characterizes A.Celli today stems from the know-how inherited from PMT in designing machinery for any type of paper, including graphic, packaging and specialty ones. A.Celli’s vision is to become a partner capable of suggesting technological solutions to companies, and not just supplying machinery. To this end, A.Celli has studied specific solutions for both large and small machines that are often forgotten by large manufacturers. One example of the great impact A.Celli can have on a paper mill’s productivity comes from the application of the shoe press, a technology that uses a larger pressing surface using a stationary shoe. The concept was developed in the 1980s by Beloit for packaging papers, where it is a priority to achieve a high paper dryness after the press section.

In the case of packaging papers, we also sought paper densification, which results, as a direct consequence, in increased mechanical strength characteristics.

It was soon understood how the shoe press concept was also of interest for graphic papers and the first applications in this field were made in 1994. PMT, which at the time was called Beloit Italia, was a pioneer in these applications. Unfortunately, in those years, the only shoe press available was the one developed for packaging papers, which proved in many cases to be oversized and too expensive for graphic papers, where specific volume and thickness are sought in order to obtain good sheet stiffness. Therefore, we required a high degree of paper dryness in order to increase production and reduce consumption, but we also need to avoid densification, which leads to a loss of stiffness (think for example of photocopy paper, which must be stiff enough to avoid curling after passing through the copier).

In 2003, PMT introduced a major innovation to the market: the SMARNIP® Mini Shoe Press, which is a shoe press specifically developed for graphic paper applications that, thanks to a shorter shoe with a variable load profile in both the machine direction and cross direction, is smaller and lighter. This innovation has enabled many paper mills equipped with small machines to access shoe press technology because of the lower investment required.

In the global paper and nonwovens markets with top-range technological solutions for over 75 years

Increased efficiency and reduced consumptions

The idea for shoe press technology arose from the fact that in conventional roller presses the pressing process has major limitations both in terms of paper dryness that can be achieved and flexibility needed to achieve the necessary quality specifications required by the paper. By achieving a higher paper dryness, we reduce energy consumption: an element of utmost importance for the survival of paper mills in a world where the cost of energy is continually rising. With a higher dryness, we also improve the plant efficiency, reducing paper breaks in the subsequent drying process. For packaging papers, where we sought densification, we obtain higher paper strength characteristics for the same raw material.

This is important, considering that the paper recycling process is a continuous cycle that, year after year, results in a deterioration in the characteristics of the raw material used. The increase in dryness is always related to an increase in densification: the distinguishing feature of the shoe press is that a higher paper dryness can be achieved compared to a conventional press for the same specific volume.