iDEAL® EvoLock® Yankee Dryer

Our new EvoLock® solution, starting from the excellent technological base of our Yankee Dryer Forged® YD, includes all the A.Celli technologies already known and appreciated, like the use of a monobloc shell forged from a single steel ingot. The novelty lies in a unique and highly innovative head-to-shell connection system, which does not require the use of structural welds or bolts. This solution allows, from an engineering point of view, to minimize the deformation of the shell edges induced by the deformation of the heads, which in itself is caused by the internal steam pressure. This important feature improves the runnability on sheet edges and consequently the efficiency of the machine.

The special design also allows to reduce the overall width of the shell, giving you the capability of drying a larger format sheet with the same existing machine gauge and, as we will analyze in the next paragraphs, to reduce the necessary inspection interventions.

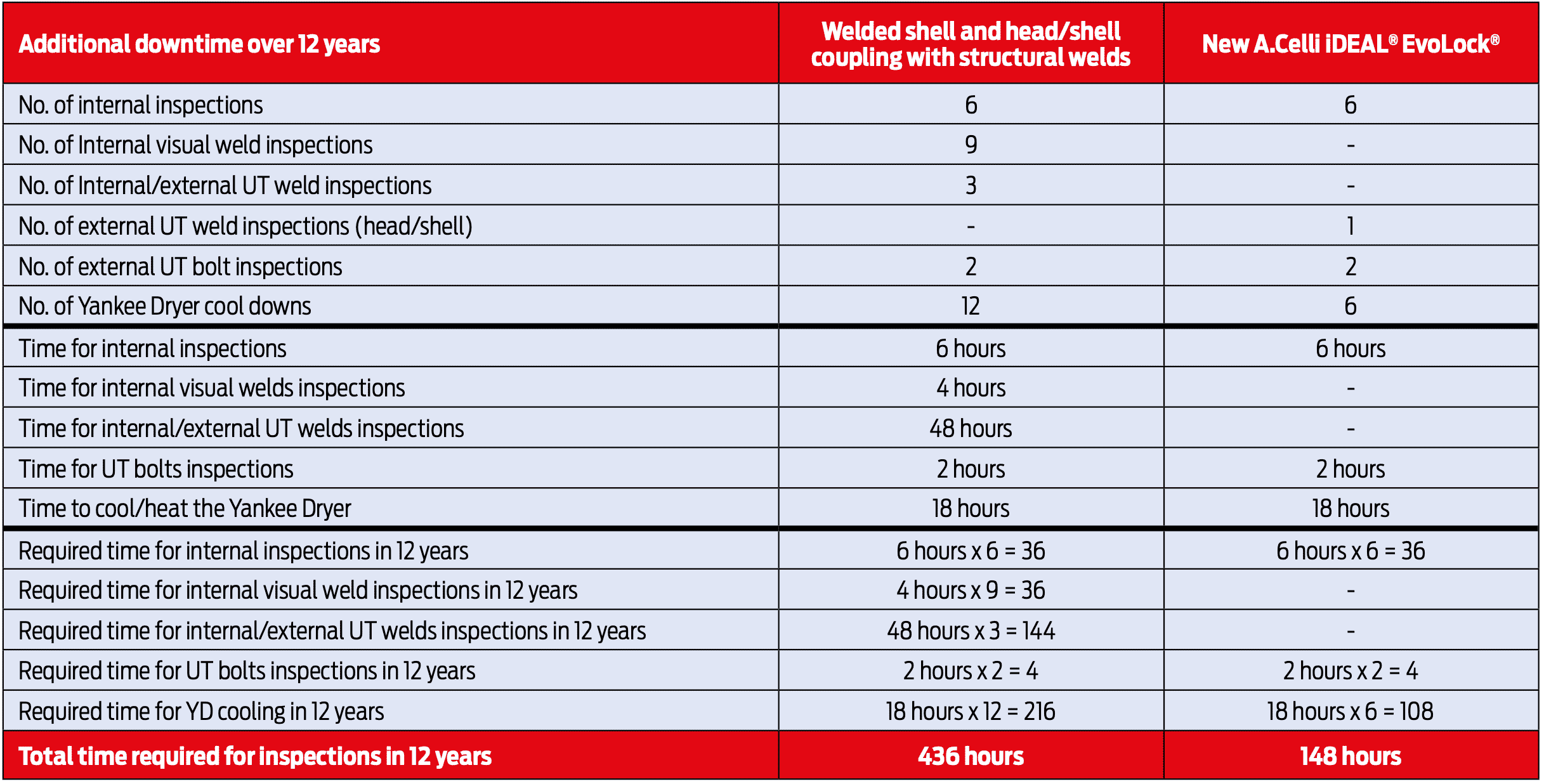

Required inspections: comparison between EvoLock® and other steel Yankee Dryers

For our analysis, we will consider two types of steel Yankee Dryer on the market:

- A traditional Yankee Dryer with welded shell and shell connected to the heads by means of full penetration structural welds.

- The new A.Celli iDEAL® EvoLock® solution, with forged shell and a new head-to-shell connection system who does not require bolts nor welds.

The following table compares the types of the required checks for the aforementioned Yankee Dryers during the first 12 years of life.